Table of Contents

The Revolutionary Role of Centrifugal Separators

When considering innovation, centrifugal separators may not be the first technology that springs to mind, but they have a significant impact on a variety of industries. These tools, which are used to separate materials with varying densities, are essential in industries like chemical processing, food production, and agriculture. Let&8217;s examine why centrifugal separators are more crucial than ever.

The Growing Importance of Efficient Separation

Industries need effective technologies to optimize processes because of the complexity of global supply chains and the drive for sustainable practices. A crucial answer to the demands for extreme precision and minimal waste is provided by centrifugal separators. Recognizing their increased significance can change how sectors respond to contemporary issues.

How Centrifugal Separators Transform Milk Processing

Centrifugal separators are crucial for the separation of cream in the dairy industry. Compared to conventional methods, they deliver products like cream and skim milk more efficiently by scaling up manufacturing processes. This has completely changed the way dairy farmers worldwide satisfy consumer demand.

Unveiling Environmental Applications

Centrifugal separators are essential for environmental management in addition to their conventional uses. By eliminating particulate matter, they help treat wastewater and produce cleaner effluent. This technology offers a useful tool for compliance efforts as environmental regulations become more stringent.

Surprising Uses in the Oil Industry

Centrifugal separators are used in the oil industry to improve fuel purity. These devices enhance refining processes by effectively removing water and impurities from crude oil. This increases profitability by lowering refinery downtime and improving product quality.

Breakthroughs in Pharmaceutical Processing

Centrifugal separators improve drug manufacturing in the pharmaceutical industry, where purity is crucial. They guarantee the accurate separation of active ingredients, improving the safety and efficacy of treatments. As the industry scrambles to develop new treatments quickly, this is essential.

Culinary Separators: Enhancing Flavors

Centrifugal separators are being used by gourmet chefs to enhance the flavors and textures of their food. Chefs can enhance culinary experiences by separating juices, oils, and fibers, proving that this adaptable technology is useful outside of the kitchen as well.

Space Exploration&8217;s Secret Weapon

Centrifugal separators are used by astronauts to purify their water while they are in space. These small devices emphasize their role in the development of extraterrestrial life support systems by ensuring sustainable life-support systems on space stations.

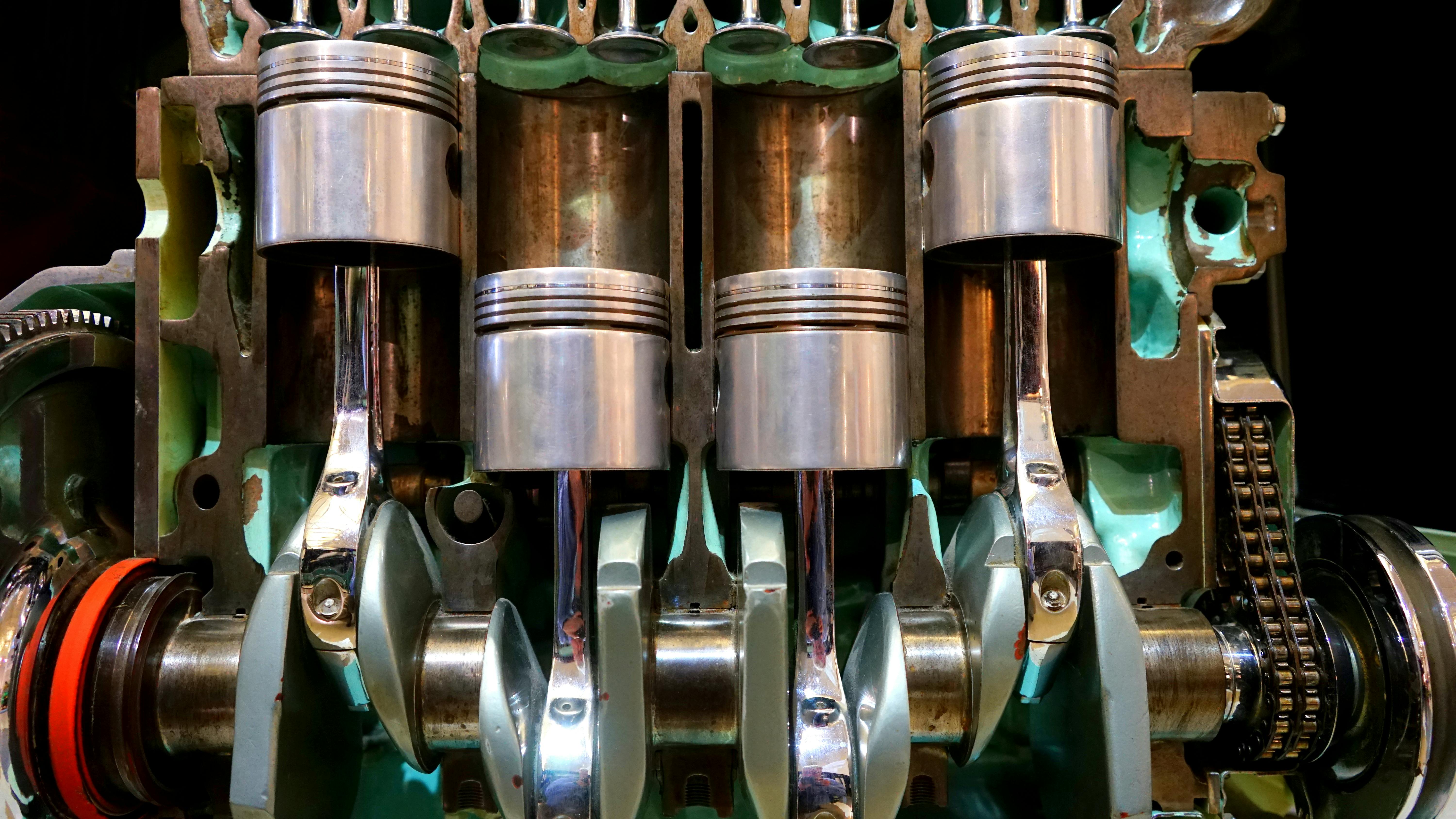

The Automotive Industry&8217;s Untapped Potential

Although frequently employed in fuel and oil purification, more recent uses in the automotive sector concentrate on recycling procedures. In the manufacturing and upkeep of vehicles, separators aid in the recovery of valuable metals and materials, supporting the circular economy.

Advancements in Biochemical Separation

Precision is essential in biochemistry. Centrifugal separators make it easier to isolate particular proteins and nucleic acids, which are essential for diagnostics and research. This precision facilitates the creation of innovative scientific and medical breakthroughs.

Optimizing Crop Yields in Agriculture

Centrifugal separators are used in agricultural industries to clean seeds and purify grains. These tools increase crop yield and seed quality by eliminating useless parts, which is essential for feeding the world&8217;s expanding population.

Enhancing Mining Efficiency

Centrifugal separators provide effective mineral processing in mining. They aid in the extraction of valuable minerals and metals from ores that have less of an adverse effect on the environment. The industry&8217;s growing emphasis on sustainable resource extraction aligns nicely with this.

Improving Textile Manufacturing Processes

Centrifugal separators are used in the textile industry to treat wastewater and recover chemicals. These devices support sustainable textile production by increasing process efficiencies and decreasing waste, satisfying the eco-friendly demands of contemporary consumers.

How Beer Brewing is Getting an Upgrade

By reducing filtration times and enhancing beer clarity, centrifugal separators have revolutionized the brewing process. Beer lovers all over the world are delighted by this technological advancement, which enables breweries to scale production while maintaining quality.

Unlocking New Horizons in Biotechnology

Centrifugal separators are used in biotechnology to isolate proteins and cells, which is essential for creating biopharmaceuticals. These separators&8217; accuracy in separation procedures spurs advancements that could transform medical treatments as biotech keeps expanding.