Table of Contents

Introduction to Capsule Filling Machines

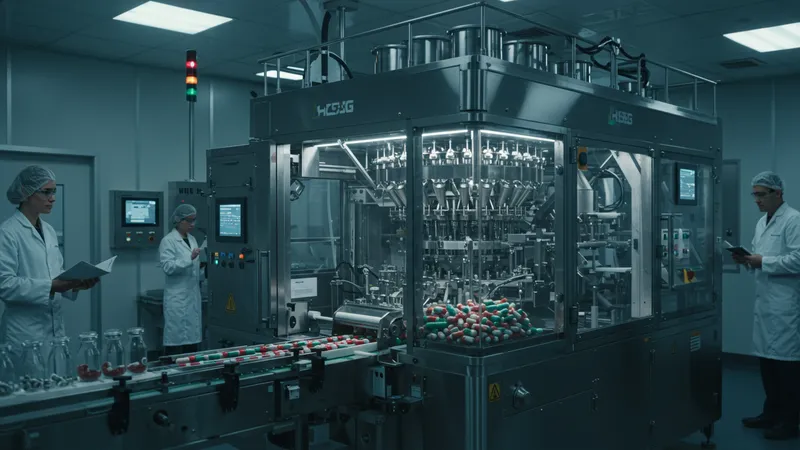

Capsule filling machines are revolutionizing the pharmaceutical and nutraceutical industries by enhancing the efficiency of pill production. These devices automate the filling of capsules with medicinal powder or granules, boosting productivity and precision. Understanding how these machines work can significantly improve your manufacturing operations. Discover why these machines are vital for modern production lines.

Why Capsule Filling Machines Are Crucial Now

As demand grows for personalized medicine and dietary supplements, the competition and production stress in these industries intensify. Capsule filling machines offer an edge by speeding up processes, reducing errors, and cutting costs. Embracing this technology may determine your market success. Are you ready to harness the potential of these powerful machines?

The Unseen Advantages of Automation

Automation in capsule filling ensures consistent quality that manual processes can&8217;t guarantee. Besides labor savings, machines eliminate human error, ensuring doses remain accurate. Such precision steers businesses towards higher customer satisfaction and compliance with stringent industry regulations. Discover how automation can turn your production woes into efficiency victories.

Exploring the Evolution of Capsule Filling Technologies

Capsule filling machines have evolved from rudimentary manual devices to sophisticated automated systems. Today&8217;s models use advanced technologies like microdosage systems and robotics. Understanding this evolution can help businesses select the right machine, aligning with contemporary demands and boosting product quality. Learn how evolution in machinery aligns with market needs.

Types of Capsule Filling Machines: Which Is Right for You?

The market offers various capsule filling machines, ranging from manual and semi-automatic to fully automatic variants. Each type caters to different production scales and specific needs. Identifying the right machine requires scrutiny of production goals and financial plans. Are you equipped with the right knowledge to choose the best machine for your operations?

Insider Tips for Maximizing Efficiency

To extract maximum value from capsule filling machines, periodic maintenance and proper calibration are key. Operators should ensure machines are regularly serviced, and components are well-aligned to prevent production hiccups. This not only extends machine lifespan but also ensures peak performance. Are you aware of all the maintenance hacks that could save you headaches?

The Surprising Power of Modular Design

Modern capsule filling machines frequently feature a modular design, allowing for scalable operations. By adjusting to production needs, these machines offer unparalleled flexibility. Businesses can start with a basic design and expand capabilities as demand grows, promoting sustainable growth. How can modular components drive innovation in your production process?

Impact on Workplace Safety and Ergonomics

Introducing capsule filling machines can vastly improve workplace safety by minimizing manual contact with medicinal powders and decreasing injury risk. Machines designed with ergonomic principles reduce operator strain. Such advancements not only protect workers but also boost morale and productivity. Could this be the missing piece to fostering a safer, happier work environment?

The Economic Benefits of Precision

Precision in capsule filling reduces waste, a critical cost factor. Accurate dosage means fewer recalls and compliance issues, translating into financial savings. By investing in precision technology, companies enhance their bottom line and market reputation. Are you implementing precision tools to economically strengthen your business?

Environmental Considerations and Sustainability

Capsule filling machines contribute to environmental sustainability by optimizing material usage and minimizing waste. More machines are being designed with eco-friendly operations in mind. By adopting greener technologies, businesses not only appeal to eco-conscious consumers but also save on costs. How green is your capsule production line?

Integration with IoT for Enhanced Performance

Internet of Things (IoT) integration in capsule filling machines provides real-time data for monitoring performance and facilitating predictive maintenance. This connectivity enhances efficiency and reduces downtime. Embracing IoT tools ensures your machinery stays ahead of the curve. Are you utilizing IoT to propel your capsule production to new heights?

Exploring Future Trends in Capsule Filling

Cutting-edge advancements such as digital twins and AI-driven analytics are reshaping capsule filling procedures. These trends forecast smarter, faster, and more personalized production. Staying updated on future trends and their potential impacts prepares businesses to adapt swiftly. How are you preparing for technological trends in capsule filling?

The Controversial Debate: Machine vs. Manual

The ongoing debate between machine-assisted and manual processes persists despite technological advancements. While machines present speed and accuracy, some argue for the craftsmanship of manual filling. Exploring both sides sheds light on decision-making factors. Do you value tradition or technology in your production philosophies?

Practical Guide: Installing and Setting Up Your Machine

Installing a capsule filling machine involves a clear understanding of space requirements and electrical needs. Proper setup ensures optimal operation and longevity. An efficient training program for operators is crucial in smoothing the transition. Are you equipped with comprehensive strategies to successfully install your new machinery?

Unlocking New Possibilities: Customization and Innovation

Customization in capsule filling machines opens innovative pathways and clearer differentiation in crowded markets. Tailored machines can focus on unique product requirements and branding strategies. Innovation ensures companies stay competitive and consumer-focused. Are you maximizing customization possibilities to stand out?